Technical

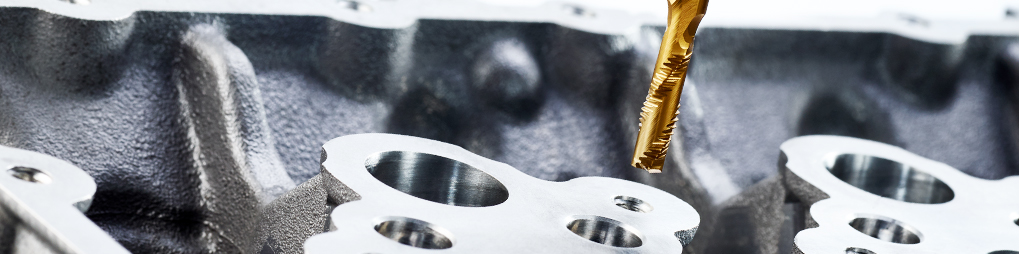

![]() Synchronised and dynamic machine axes of the CNC- machining center

Synchronised and dynamic machine axes of the CNC- machining center

![]() Stable clamping of the component

Stable clamping of the component

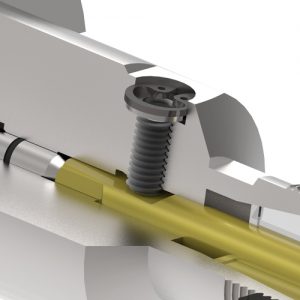

![]() Control unit of the machine tool has a program for the Punch Tap cycle. Please contact therefor your machine tool builder or control unit supplier.

Control unit of the machine tool has a program for the Punch Tap cycle. Please contact therefor your machine tool builder or control unit supplier.

![]() Lubricants: coolant-lubricants, cutting oils or MQL

Lubricants: coolant-lubricants, cutting oils or MQL

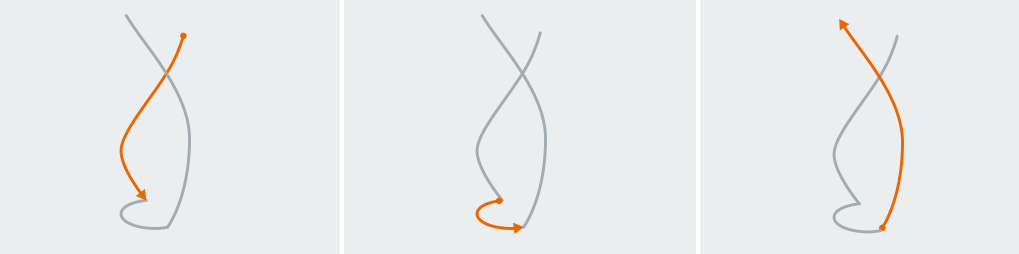

Pre-drilling

The helical cold-forming of an internal thread requires a cylindrical pre-drilled hole with a diameter smaller than the nominal diameter of the thread.

Example:

Standard thread M6, pitch 1,0 mm

![]() pre-drilled hole ø 5,55 mm (specified by tool manufacturer)

pre-drilled hole ø 5,55 mm (specified by tool manufacturer)

![]() 90° conical counterboring (e.g. 6,3 mm diameter for M6, accord. to DIN 76-1:2004-06)

90° conical counterboring (e.g. 6,3 mm diameter for M6, accord. to DIN 76-1:2004-06)

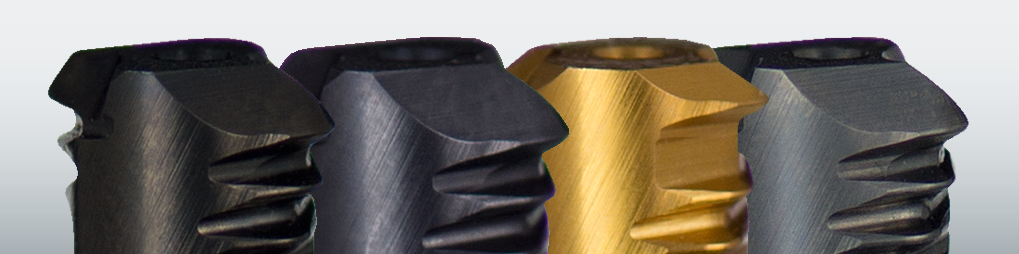

Economic Efficiency

The economic efficiency of the threading technology is the result of a high number of threads and the time savings achieved with shorter machining time.