Kinematics

The basic movement path of this process consists of 3 steps described in the following:

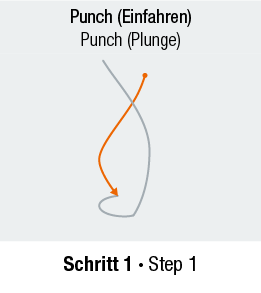

1. Plunge/ Production of groove

Upon entering the predrilled hole, the first tooth (broaching tooth) of each flute produces a groove. The helical infeed into the pre-drilled tap hole moves the Punch Tap to the application depth. This first process step does not yet produce a thread.

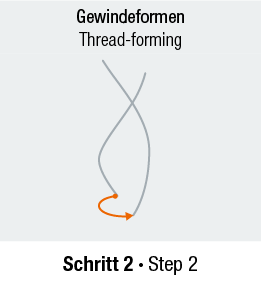

2. Cold-forming

Once the Punch Tap has reached its depth of application, the cold-forming of thread starts. This is achieved with a synchronous movement of feed and rotation. The thread is produced with a half left-turn in the pitch. Each tooth of the Punch Tap produces half a thread (approx. 180°).

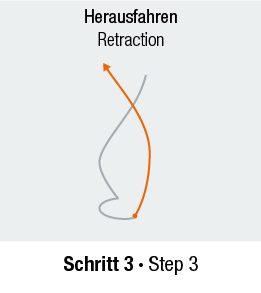

3. Retraction

After the threads have been formed, the Punch Tap is retracted in a helical movement from the bore hole using the path of the produced grooves.

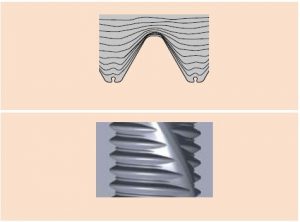

Result

The finished cold-formed thread is interrupted by two helical grooves offset-by 180°. From a depth of thread of 2xD, the static strength is not adversely affected.

![]() Continuous fibre structure

Continuous fibre structure

![]() Work hardened workpiece material

Work hardened workpiece material

![]() Unformed core

Unformed core

![]() Helical grooves

Helical grooves

![]() Cold-forming completed with half a turn

Cold-forming completed with half a turn